Lab 6 Report

In this lab, we implemented a PID controller for the orientation (theta) of the robot.

Prelab

The requirements for the prelab are identical to Lab 5, and I have implemented it in the same way. So for the sake of brevity, I will not be copying the same text over; please refer to Lab 5 for my Prelab for Lab 6.

Lab Tasks

PID Input Signal Discussion Questions

- Are there problems that digital integration may cause? The gyroscope is not perfectly accurate (i.e. when the robot is not spinning, the average reading from the gyroscope will not be 0 degrees/sec). To get a heading in degrees, we integrate this reading from the gyroscope. Since there is an average offset in the input signal, integrating that signal will cause the integral to slowly drift from the correct value at a constant rate. Since there isn’t a simple way to fuse the data from the gyroscope with the accelerometer in yaw (which is what we want), this error will accumulate over time and cause significant problems (the robot will slowly turn over time).

- Are there ways to minimize these problems? Perhaps doing some more complicated sensor fusion (for example, using the centripetal force experienced by the accelerometer when the robot turns about its yaw axis) or incorporating the magnetometer data (which should also detect when the robot turns about the yaw axis) would help to stabilize the integration of the gyroscope data. We could also add some sort of calibration on the gyroscope and subtract the observed constant offset in the gyroscope reading from every gyroscope data point before integrating. But this solution is not very robust.

- Does sensor have any bias? Yes, as mentioned above, the gyroscope exhibits some constant bias (i.e. when the IMU is not moving, the gyroscope still says that the robot is rotating).

- How fast does the error grow as a result of the bias? The gyroscope’s constant yaw bias is around 6 degress/sec, as can be seen in my Lab 2 report. When integrating, this is also the rate at which the error grows (around 6 degrees/sec). I will use the onboard Digital Motion Processor (DMP) to counteract this drift!

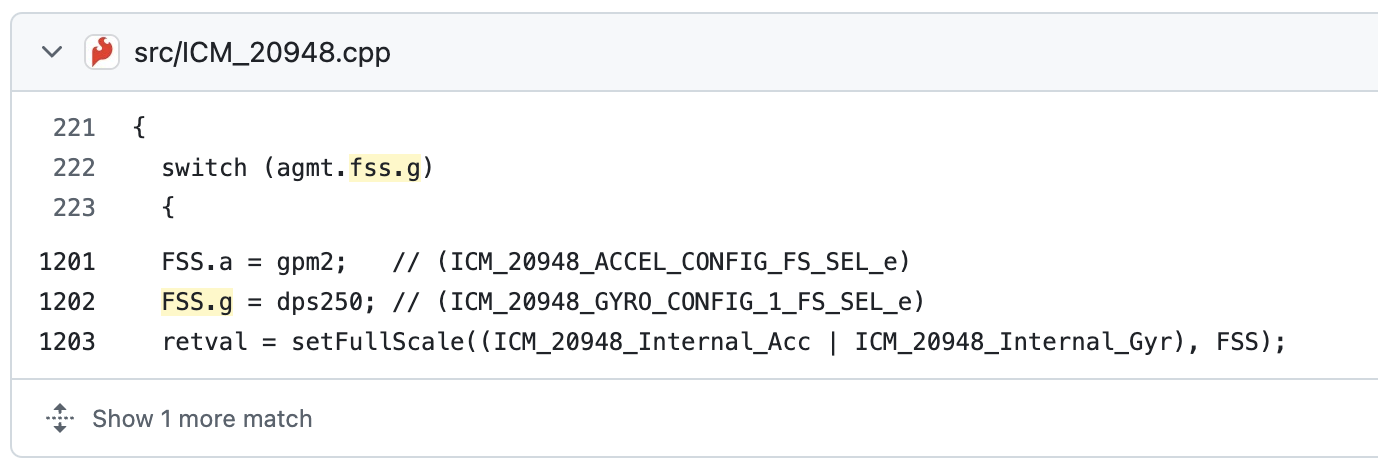

- Are there limitations to the sensor to be aware of? The gyroscope is by default set to have a maximum spin rate of 250 degrees/sec (dps), as shown in this code snippet from the Arduino library Github:

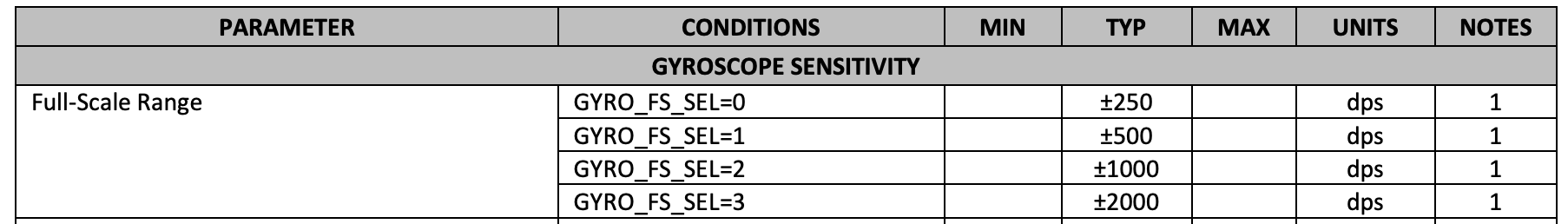

Here is a screenshot of the datasheet confirming that there are indeed four different ranges that you can set it to:

- Is this maximum spin rate sufficient for our applications? 250 dps is around 70% of a full rotation per second. This robot can spin much faster than that, so it may not be enough for our applications.

- Are there ways to configure this parameters? Looking at the code and datasheet, it looks like we can set the

GYRO_FS_SELregister of the gyroscope to1,2, or3, for a dps of500,1000, or2000dps, respectively.

Derivative Term Questions

- Does it make sense to take the derivative of an integral? From a calculus / math perspective, it’s perfectly valid to take the derivative of an integral; you just get the original signal back. In our case, if we are using the onboard DMP, the integrated signal is going to be a calculated signal which is the result of accelerometer, gyroscope, and magnetometer sensor signals. It won’t be simply the integral of any one sensor signal. So, though the measured yaw angle will be, to a first order, the integral of the gyroscope measured spin rate about a particular axis, the integrated yaw angle will be its own signal, which means taking the derivative of it makes perfect sense.

- Does changing the setpoint while robot is running cause problems? Yes, there will be a deriviative kick whenever you change the setpoint. This will cause a large change in the output whenever you change the setpoint.

- Is a low-pass filter needed before your derivative term? Yes, we will need a low-pass filter on the derivative term to smooth out any derivative kicks.

Programming Implementation

- Can you process Bluetooth commands while controller is running? Yes. Nothing in the PID Control function hangs (waits for sensor values or delays), and it is called in the

whileloop that runs when the Bluetooth is connected. My PID control algorithm is written and called in exactly the same way as Lab 5, so I won’t repeat it for the sake of brevity here. - Think about future applications with navigation or stunts. Will you need to be able to update setpoint in real time? Yes, I will need to be able to update the setpoint in real time. As the robot drives and plans its actions, it’ll need to be able to set its desired orientation internally, and the PID control loop will have to execute to get the robot to actually obtain the desired state.

- Can you control the robot’s orientation will driving forward and backward? How would this be implemented? Yes, I can do this by running the PID control loop for driving straight (Lab 5) simultaneously with the PID control loop for controlling the orientation (Lab 6), and combining the two outputs for the motor directions.

- How can I make implementing #3 simple in the future? I can write a general PID algorithm that operates on a set of gains, input data, etc., so that when running the two PID loops simultaneously, I won’t need to have two copies of my PID algorithm code. I can write a general

move()function which can accomodate assymetrical motor speed requests (i.e. the absolute value of the speed commanded to one motor is different from that of the other motor).

Orientation PID Control

I used DMP and followed the instructions on the link on the lab manual to set it up. Here is the code in the setup() function that I added:

bool success = true;

// Initialize the DMP

success &= (myICM.initializeDMP() == ICM_20948_Stat_Ok);

// Enable the DMP Game Rotation Vector sensor

success &= (myICM.enableDMPSensor(INV_ICM20948_SENSOR_GAME_ROTATION_VECTOR) == ICM_20948_Stat_Ok);

// Set the DMP output data rate (ODR): value = (DMP running rate / ODR ) - 1

// E.g. for a 5Hz ODR rate when DMP is running at 55Hz, value = (55/5) - 1 = 10.

success &= (myICM.setDMPODRrate(DMP_ODR_Reg_Quat6, 0) == ICM_20948_Stat_Ok); // Set to the maximum

// Enable the FIFO queue

success &= (myICM.enableFIFO() == ICM_20948_Stat_Ok);

// Enable the DMP

success &= (myICM.enableDMP() == ICM_20948_Stat_Ok);

// Reset DMP

success &= (myICM.resetDMP() == ICM_20948_Stat_Ok);

// Reset FIFO

success &= (myICM.resetFIFO() == ICM_20948_Stat_Ok);

// Check success

if (!success) {

Serial.println("Enabling DMP failed!");

while (1) {

// Freeze

}

}

In my loop(), I make sure that regardless of if the PID loop is running, that I am constantly reading data from the FIFO from the DMP, to prevent the IMU from crashing. If my PID loop is running, I get the data and calculate the yaw angle, as per the example DMP code. Here is the loop() code pertaining to the IMU:

// While central is connected

while (central.connected()) {

// read data from the FIFO no matter what

myICM.readDMPdataFromFIFO(&data);

// if want to run pid loop

if (run_pid_loop) {

// Is valid data available and space in array?

if ((imu_arr_ix < imu_log_size) && ((myICM.status == ICM_20948_Stat_Ok) || (myICM.status == ICM_20948_Stat_FIFOMoreDataAvail))) {

// We have asked for GRV data so we should receive Quat6

if ((data.header & DMP_header_bitmap_Quat6) > 0) {

q1 = ((double)data.Quat6.Data.Q1) / 1073741824.0; // Convert to double. Divide by 2^30

q2 = ((double)data.Quat6.Data.Q2) / 1073741824.0; // Convert to double. Divide by 2^30

q3 = ((double)data.Quat6.Data.Q3) / 1073741824.0; // Convert to double. Divide by 2^30

// calculate yaw (copied from the example code)

q0 = sqrt(1.0 - ((q1 * q1) + (q2 * q2) + (q3 * q3)));

qw = q0;

qx = q2;

qy = q1;

qz = -q3;

// yaw (z-axis rotation)

t3 = +2.0 * (qw * qz + qx * qy);

t4 = +1.0 - 2.0 * (qy * qy + qz * qz);

yaw = atan2(t3, t4) * 180.0 / PI;

// put the calculated value into the array

imu_yaw[imu_arr_ix] = yaw;

imu_times[imu_arr_ix] = micros();

imu_arr_ix++;

// send new pwms to the robot

run_pid();

}

}

}

// Send data

write_data();

// Read data

read_data();

}

Since the IMU generates data at a much faster rate than the ToF sensor, I didn’t notice much of a difference in performance between decoupling and coupling the two loop rates. So I left them coupled, as it simplifies the code significantly and makes debugging much easier (decoupling the loops made the control loop run at more than 1000 Hz, which took an extremely long time to send over to the computer).

The PID algorithm is implemented the exact same way as in Lab 5. See that lab for more details; I simply replaced the line to calculate the error from:

float err = (tof_arr_ix == 0) ? 0.0 : tof_data_two[tof_arr_ix - 1] - SETPOINT;

to

float err = imu_yaw[imu_arr_ix - 1] - SETPOINT;

I kept the low-pass-filter implementation for the derivative term, in order to account for derivative kick when changing the setpoint.

I slightly modified my straight() function from Lab 5 to come up with a spin function for Lab 6, which is shown here. For an explanation for why this is useful / necessary, see my Lab 5 report:

/*

* Sends the requested speed in pwm units to the motors,

* with an offset of the DEADBAND defined above

*/

void spin(float pwm) {

const float stoprange = 3.0;

int adjusted_pwm_one = 0;

int adjusted_pwm_two = 0;

if (abs(pwm) < stoprange) {

analogWrite(MTR1_IN1, 0);

analogWrite(MTR1_IN2, 0);

analogWrite(MTR2_IN1, 0);

analogWrite(MTR2_IN2, 0);

} else if (pwm >= stoprange) {

adjusted_pwm_one = (int) (pwm * CALIB_FAC + DEADBAND + 0.5);

adjusted_pwm_two = (int) (pwm + DEADBAND + 0.5);

analogWrite(MTR1_IN1, adjusted_pwm_one);

analogWrite(MTR1_IN2, 0);

analogWrite(MTR2_IN1, adjusted_pwm_two);

analogWrite(MTR2_IN2, 0);

} else {

adjusted_pwm_one = (int) (pwm * -1.0 * CALIB_FAC + DEADBAND + 0.5);

adjusted_pwm_two = (int) (pwm * -1.0 + DEADBAND + 0.5);

analogWrite(MTR1_IN1, 0);

analogWrite(MTR1_IN2, adjusted_pwm_one);

analogWrite(MTR2_IN1, 0);

analogWrite(MTR2_IN2, adjusted_pwm_two);

}

}

I also added another command to change the setpoint of the controller, SET_SETPOINT, which is implemented as follows on the Arduino side:

/*

* Set the setpoint for the PID controller

*/

case SET_SETPOINT:

// Extract the next value from the command string as a float

success = robot_cmd.get_next_value(SETPOINT);

if (!success)

return;

break;

To test and tune my PID controller on the Python side, I wrote this test:

imu_yaw = list()

imu_times = list()

ctrl_outputs = list()

setpoint_arr = list()

p_outputs = list()

i_outputs = list()

d_outputs = list()

ctrl_times = list()

def pid_log_notification_handler(uuid, characteristic):

s = ble.bytearray_to_string(characteristic)

strs = s.split('|')

if (strs[0] == '1'):

imu_times.append(int(strs[1]))

imu_yaw.append(float(strs[2]))

else:

ctrl_times.append(int(strs[1]))

ctrl_outputs.append(float(strs[2]))

setpoint_arr.append(float(strs[3]))

p_outputs.append(float(strs[4]))

i_outputs.append(float(strs[5]))

d_outputs.append(float(strs[6]))

ble.start_notify(ble.uuid['RX_STRING'], pid_log_notification_handler)

# run pid loop for some number of seconds

time_between_turns = 1;

ble.send_command(CMD.SET_SETPOINT, 90.0);

ble.send_command(CMD.START_PID_MVMT, "");

time.sleep(time_between_turns);

ble.send_command(CMD.SET_SETPOINT, 0.0);

time.sleep(time_between_turns);

ble.send_command(CMD.SET_SETPOINT, -90.0);

time.sleep(time_between_turns);

ble.send_command(CMD.SET_SETPOINT, 0.0);

time.sleep(time_between_turns);

ble.send_command(CMD.STOP_PID_MVMT, "");

# clear the lists, then send command to get data back

imu_yaw.clear()

imu_times.clear()

ctrl_outputs.clear()

setpoint_arr.clear()

p_outputs.clear()

i_outputs.clear()

d_outputs.clear()

ctrl_times.clear()

ble.send_command(CMD.SEND_PID_LOGS, "");

# Subtract first time from times to get 0-indexed time for both arrays

first_time = int(ctrl_times[0])

for i in range(len(imu_times)):

imu_times[i] -= first_time

imu_times[i] /= 1000000.0 # convert to seconds

for i in range(len(ctrl_times)):

ctrl_times[i] -= first_time

ctrl_times[i] /= 1000000.0 # convert to seconds

# Make a plot of control data

plt.figure(figsize = (12, 4))

plt.plot(ctrl_times, ctrl_outputs, 'r', label = "Control Output")

plt.plot(ctrl_times, p_outputs, 'g', label = "Prop. Branch")

plt.plot(ctrl_times, i_outputs, 'b', label = "Int. Branch")

plt.plot(ctrl_times, d_outputs, 'm', label = "Deriv. Branch")

plt.xlabel('Time (s)')

plt.ylabel('Control Output (PWM units)')

plt.legend()

plt.show()

# Make a plot of IMU datahttps://cdn.sparkfun.com/assets/learn_tutorials/8/9/3/DS-000189-ICM-20948-v1.3.pdf

plt.figure(figsize = (12, 4))

plt.plot(imu_times, imu_yaw, 'r', label = "IMU Yaw")

plt.plot(imu_times, setpoint_arr, 'b', label = "Set Point")

plt.xlabel('Time (s)')

plt.ylabel('Heading (degrees)')

plt.legend()

plt.show()

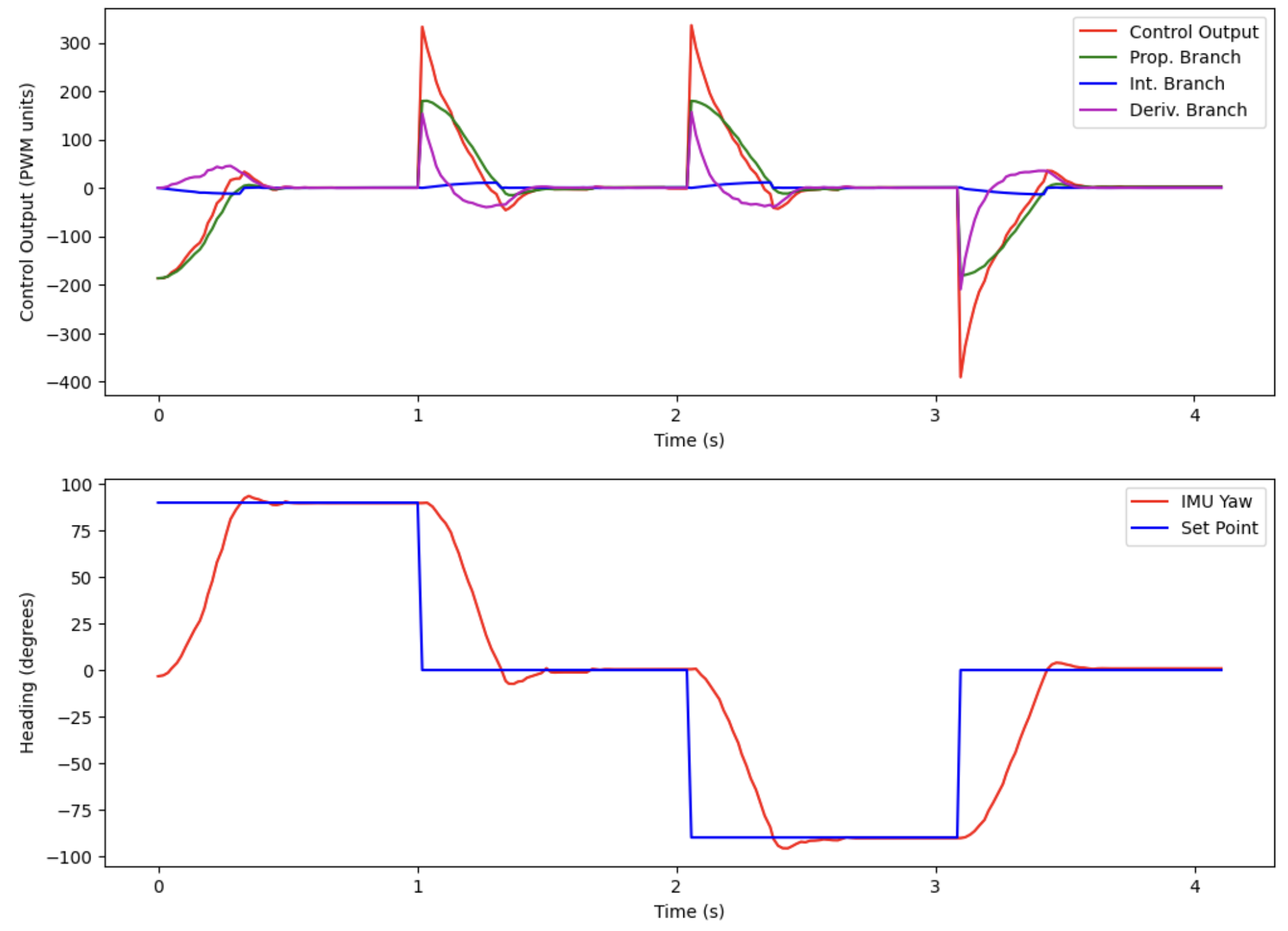

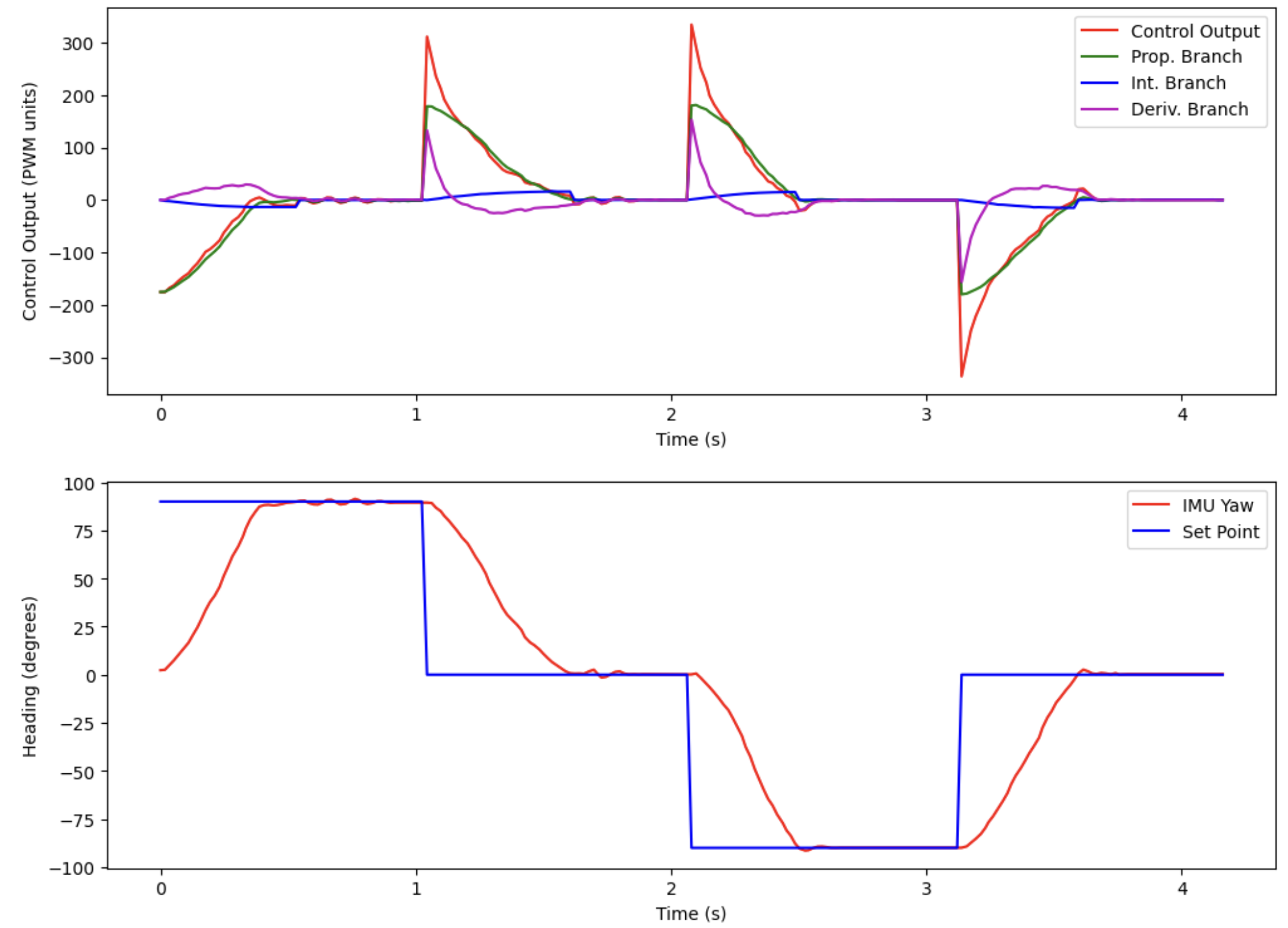

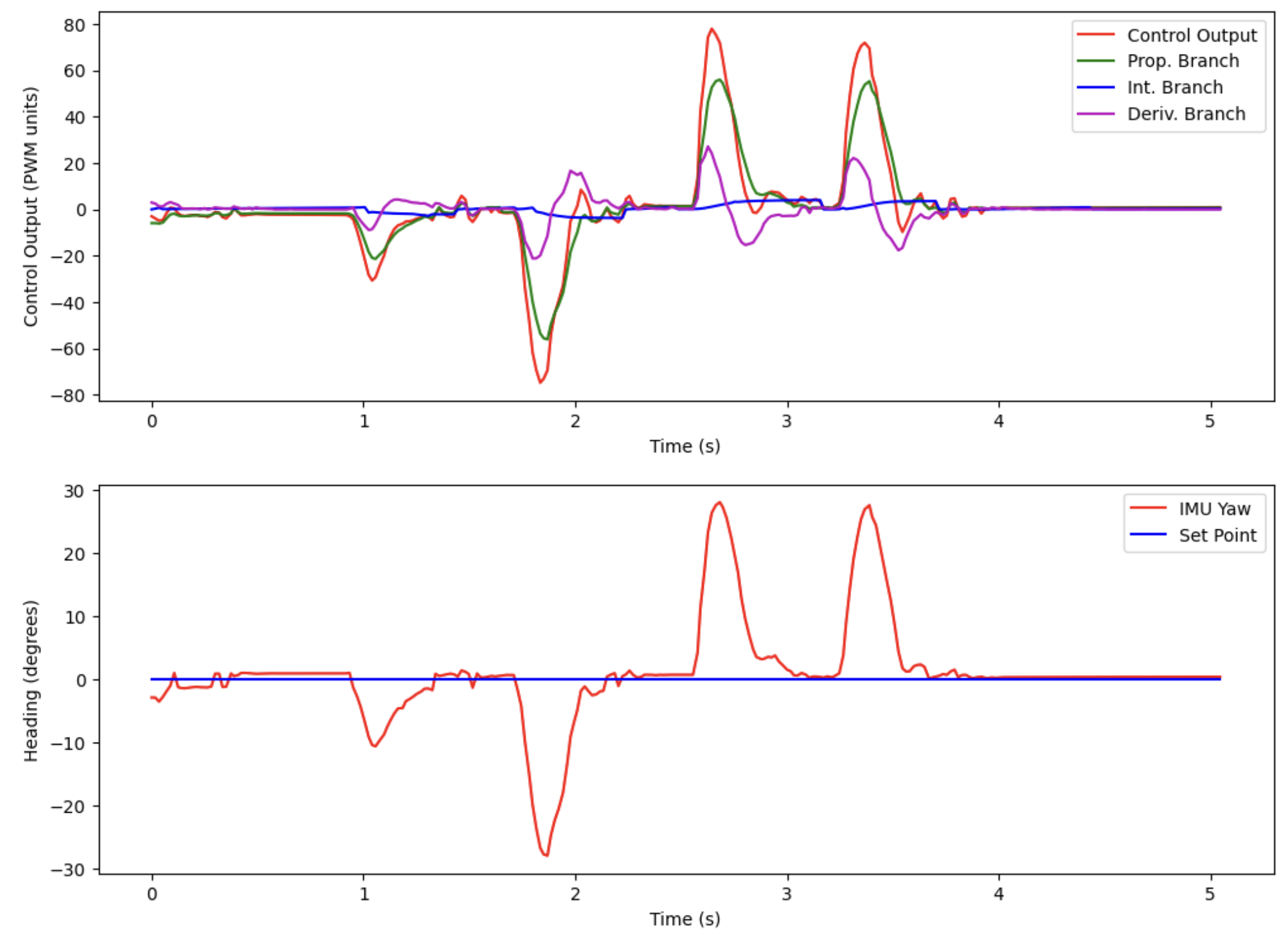

This code runs a test starting at a heading of 0 degrees. It turns the robot 90 degrees to the right and back, and then 90 degrees to the left and back. After tuning, the values the I settled on were as follows:

- Kp = 2.0

- Ki = 0.7

- Kd = 0.1

- Derivative LPF alpha = 0.3

Below is a video of the robot executing the test on a smooth surface:

And here is the plot associated with this movement:

Below is a video of the same test being executed on a carpeted surface:

And here is the plot associated with this movement:

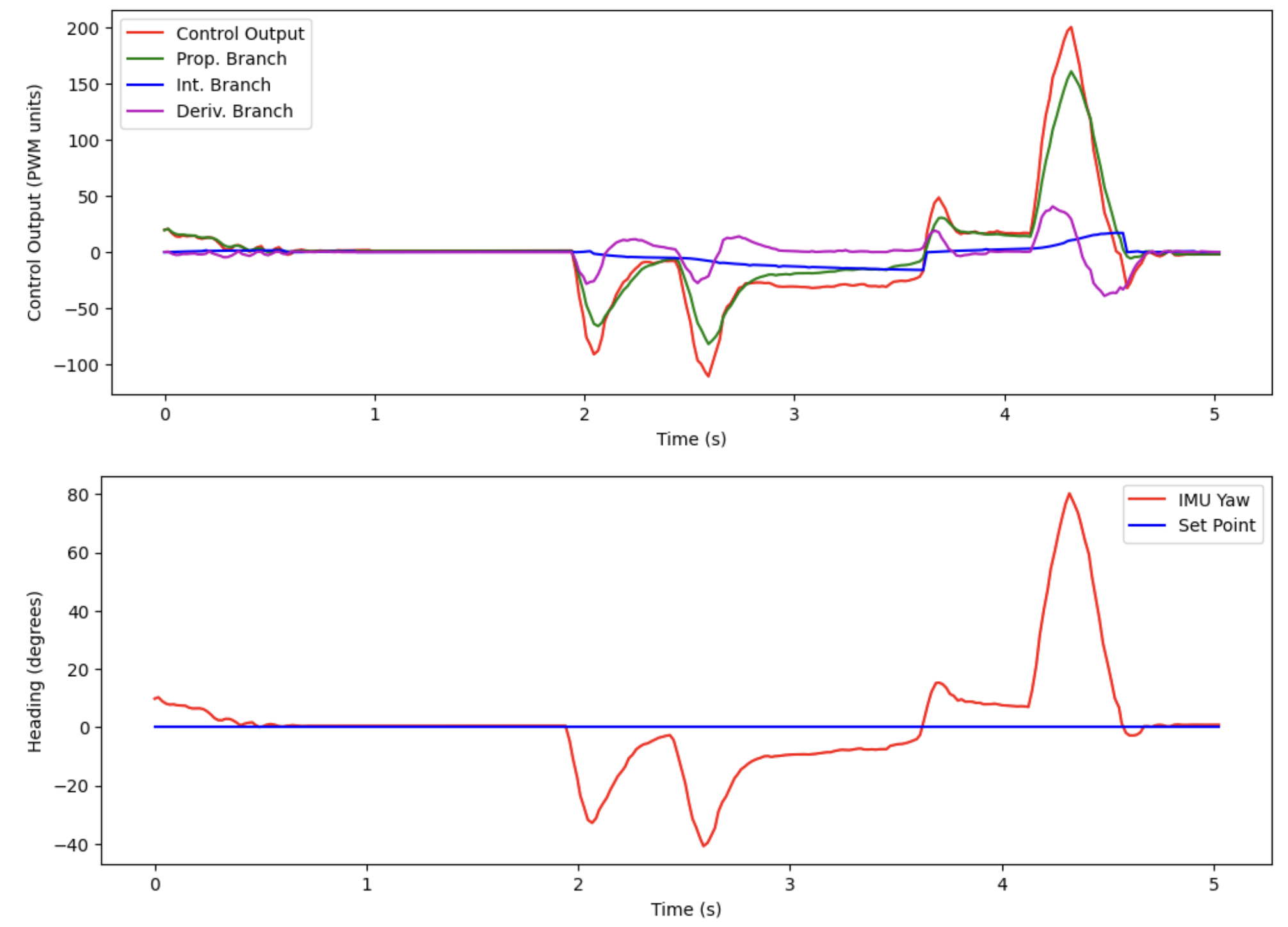

Below is a video of the robot responding to external disturbances on a smooth surface:

And here is a plot associated with this movement:

Below is a video of the robot responding to external disturbances on a carpeted surface:

And here is a plot associated with this movement:

Some notable observations and comments from these results:

- The controller generally performs better (fewer oscillations, faster settling time) on the hardwood floor, compared to the carpeted floor. This is because the carpeted floor is more difficult for the robot to turn on (the wheels don’t scrub as easily)

- Since it is more difficult to successfully control the robot on the carpet, the PID gains were first tuned on the carpeted surface, and then run on the hardwood surface to see if the performance was the same (in both tests, this was the case). As soon as I found the gains mentioned previously which worked on the carpet, those same gains gave (even better) results on the hardwood surface.

- The robot can have the same performance with much less aggressive gains on the hardwood surface, compared to the carpet.

- The integral gain Ki is very important to maintain good performance on the carpet. For small errors, the proportional term (Kp * error) is not going to be large enough to overcome the static friction presented by the carpet. Thus, for small errors, we need to have a quickly accumulating integral term to help push the robot all the way to the setpoint.

- However, on the hardwood, having a large integral gain to push the robot all the way to the setpoint becomes a huge problem, since the robot easily overshoots the setpoint on hardwood. We need to add integral windup protection to maintain good performance on the hardwood surface as well. This caps the integral branch to a maximum value, and allows the robot to recover quickly if it has overshot the setpoint.

- Notice that there is no derivative kick; that is the low-pass-filter on the derivative term in action!

A final note on the code is that we ended up needing to increase the maximum deg/sec that the gyroscope can sense. We did this by adding the following code before the DMP setup in the setup() function:

// increase the maximum deg/sec gyroscope can sense

ICM_20948_fss_t myFSS; // This uses a "Full Scale Settings" structure that can contain values for all configurable sensors

myFSS.g = dps1000; // (ICM_20948_GYRO_CONFIG_1_FS_SEL_e)

myICM.setFullScale(ICM_20948_Internal_Gyr, myFSS);

This allowed the robot to accurately spin at full speed while traversing from one setpoint to another.

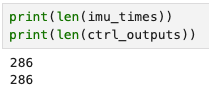

Finally, I also measured the sampling rate of the IMU with the DMP, just to ensure that it’s a reasonable rate. After running the test for disturbance tests, which lasted 5 seconds, I printed out the length of the arrays of data that were returned by the Artemis. Here is a screenshot:

We can see that we received 286 data points in 5 seconds, which works out to 57 Hz. This should be fast enough for our purposes (and is certainly much faster than the 15-20 Hz we get from the ToF sensor). We’ll notice that the sampling rate is lower than observed in lab 2, and that is because of the extra processing the DMP has to do in order to report new data.

Acknowledgements

- Sophia Lin (lab partner, helping me record videos)

- Datasheet for the IMU

- Sparkfun IMU Breakout Board Arduino Library Github Page